About ATS Safety

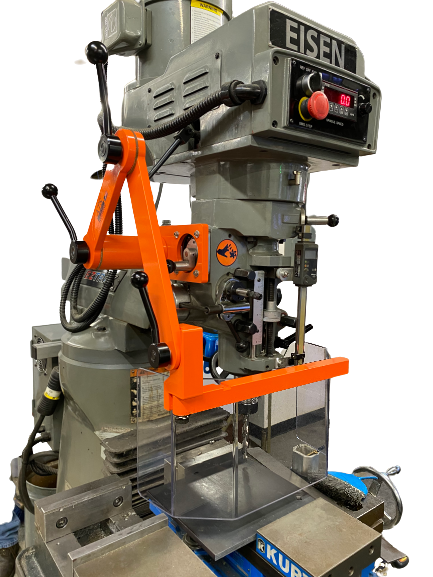

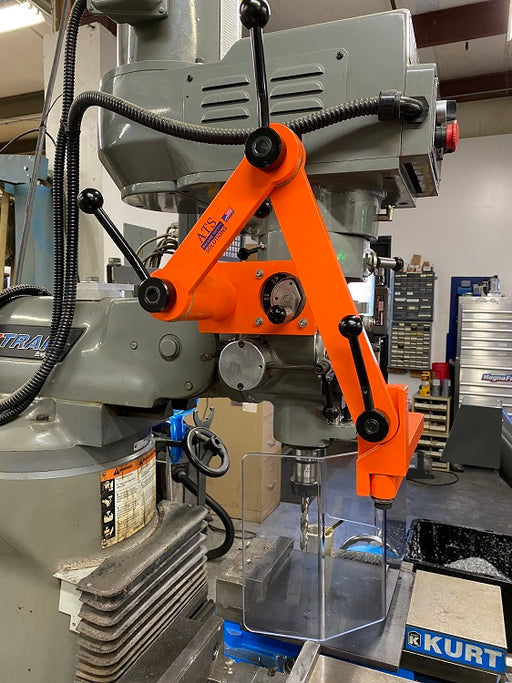

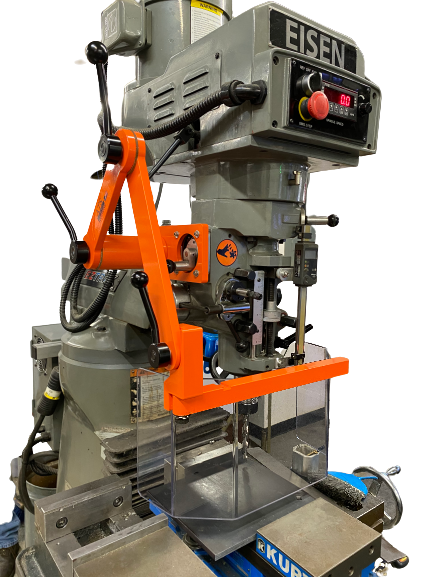

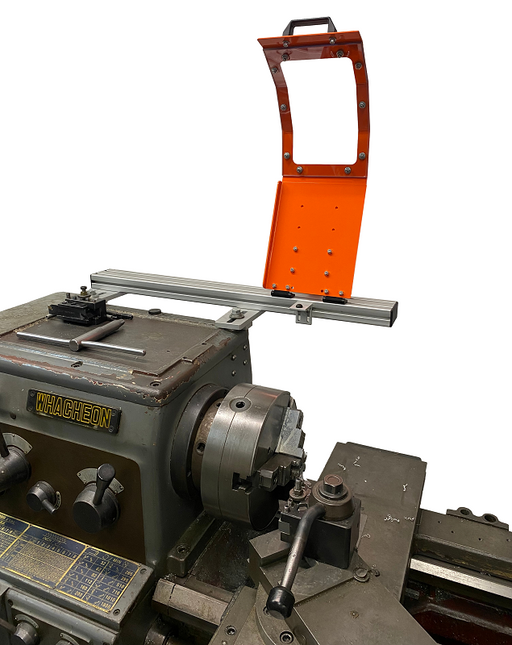

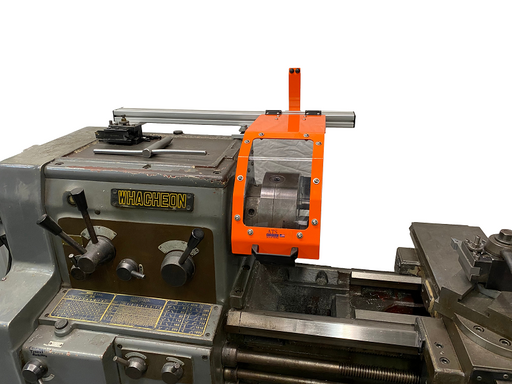

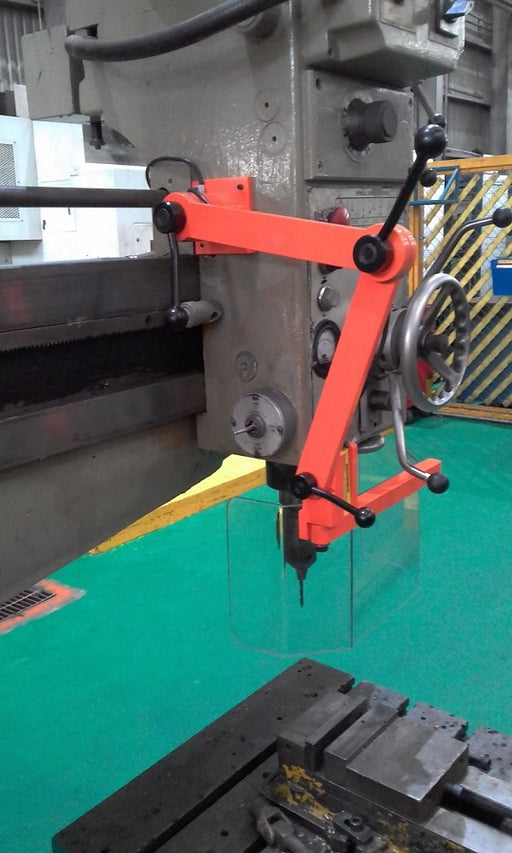

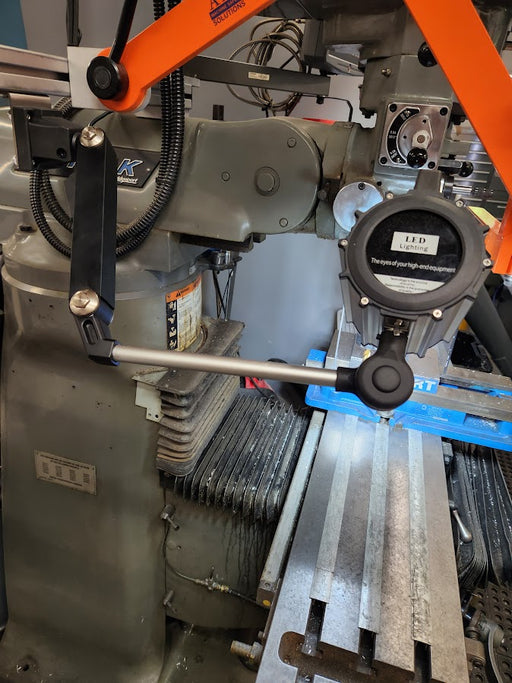

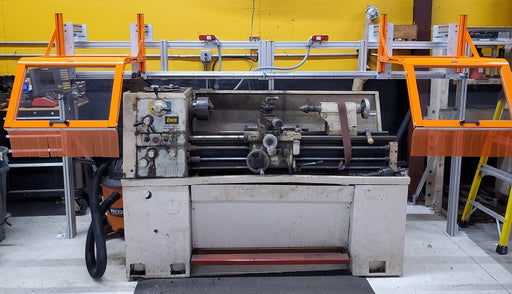

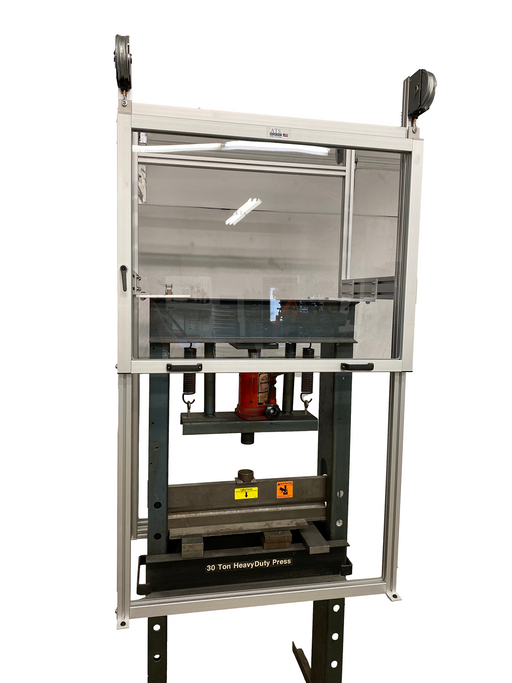

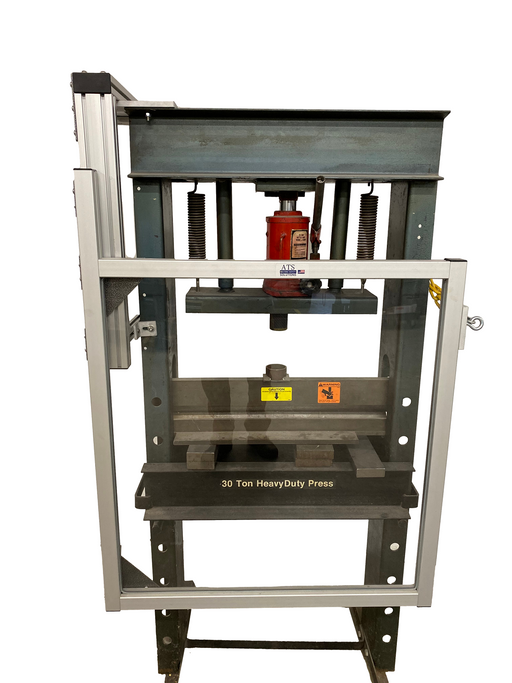

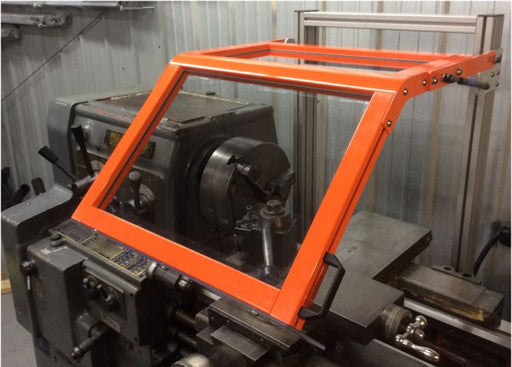

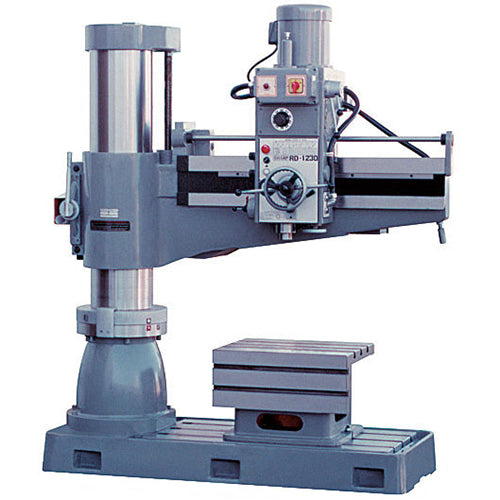

We offer a wide variety of machine tool safety guards and shields for milling machines, drill presses, lathes, grinders, hydraulic presses and more. In addition to our stock products, we build custom tailored guards for lathes, hydraulic presses, and other machinery used in the metalworking industry and found in maintenance shops. We are trusted by hundreds of customers every year, many repeat, who rely on us to help them protect their employees from workplace hazards and avoid OSHA fines. Our customers come from any industry you can imagine, including Aerospace, Automotive, Consumer Products and Packaging, Energy, Oil/Gas, Transportation, Marine, Medical Devices, Pharmaceutical, Government & Defense, and many others! All of our machine safety products are proudly made in the USA!